Mobile Belt Presses

BP-1100 2.2 M Komline

- Belt Press has a large gravity zone and 2 dewatering (dandy) rollers.

- Large air conditioned control room

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- BP-1100 Trailer: Year – 1996, Make/Model-Utility/UT,

- 11′ 11″ Wide x 49′ Long

- Weight: 56,000 lbs.

- VIN#-1UYTS2531TA861208

- License Plate – Y62343

BP-1200 2.2 M Ashbrook

BP-1300 2.2 M Ashbrook

BP-1500 2.1 M 3 Belt BDP

BP-1600 2.2 M Ashbrook

BP-1700 2.2 M Andritz SMX-7

BP-1800 2.2 M Andritz SMX-7

BP-1900 2.2 M Andritz SMX-7

BP-6100 2.2 M Komline

BP-7100 2.2 M Ashbrook

BP-9000 2.2 M Ashbrook

BP-9100

Skid Mounted Belt Presses

BP-2000 2.2 M Ashbrook

BP-2500 2.2 M Ashbrook

BP-2600 2.2 M Ashbrook

(Skid Press)

- Extended Gravity Zone

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- 4″ Sludge Feed pump

- 12′ extension for Conveyor cake discharge (20′ overall)

- Comes with its own step deck trailer for low profile or trailer mounted applications

- BP-2600 Trailer: Year-1998, Make/Model-Wabash

- 11′ 11″ Wide x 49′ Long x 13’6″ Height

- Weight: 49,000 lbs.

- VIN#-1JJF452WXWL504048

- License Plate-016B014

BP-2700 2.2 M Ashbrook

(Skid Press)

- Extended Gravity Zone

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- BP-2700 Trailer: Year-1997, Make/Model-Fona

- 11′ 11″ Wide x 49′ Long x 13′ Height

- Weight: 48,000 lbs.

- VIN#-13N24S30XV1570558

- License Plate-016B012

BP-3000 2.2 M Ashbrook

- Stainless Steel Catwalks

- Standard Gravity Zone

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- 4″ Sludge Feed pump

- 12′ extension for Conveyor cake discharge (20′ overall)

- Comes with its own step deck trailer for low profile or trailer mounted applications

- BP-3000 Trailer: Year-1999

- 11′ 11″ Wide x 48′ Long x 13′ Height

- Weight: 48,000 lbs

- VIN#-13N248305X5985892

- License Plate-084C597

BP-4400 2.2 M Ashbrook

- Stainless Steel Catwalks

- Standard Gravity Zone

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- 4″ Sludge Feed pump

- 12′ extension for Conveyor cake discharge (20′ overall)

- Comes with its own step deck trailer for low profile or trailer mounted applications

- 11′ 11″ Wide x 48′ Long x 13′ Height

- Weight: 49,000 lbs.

- BP-4400 Trailer: Year-1999, Make/Model-TALB

- VIN#-40FL04821X1018728

- License Plate-121C305

BP-4500 2.2 M Ashbrook

Stainless Steel Catwalks

- Standard Gravity Zone

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- 4″ Sludge Feed pump

- 12′ extension for Conveyor cake discharge (20′ overall)

- Comes with its own step deck trailer for low profile or trailer mounted applications

- 11′ 11″ Wide x 48′ Long x 13′ Height

- Weight: 48,000 lbs.

- BP-4500 Trailer: Year-2009

- VIN#-13N24820581546934

- License Plate – 110B800

BP-4600 2.2 M Ashbrook

Stainless Steel Catwalks/ Handrails

- Standard Gravity Zone

- Pumps and press have electronic VFD controls

- Automated emulsion Polymer make down system

- 4″ Sludge Feed pump

- 12′ extension for Conveyor cake discharge (20′ overall)

- Comes with its own step deck trailer for low profile or trailer mounted applications

- 10′ 7″ Wide x 25′ Long x 9’2″ Height

- Weight: 48,000 lbs.

- BP-4600 Trailer: Year – 2009, Make/Model – FonTaine

- VIN#-13N24820591550130

- License Plate – 110B801

BP-5100 2.2 M Ashbrook

BP-8100 1 M Parkson

Other Equipment

GBT-1000 – 2 Meter Parkson

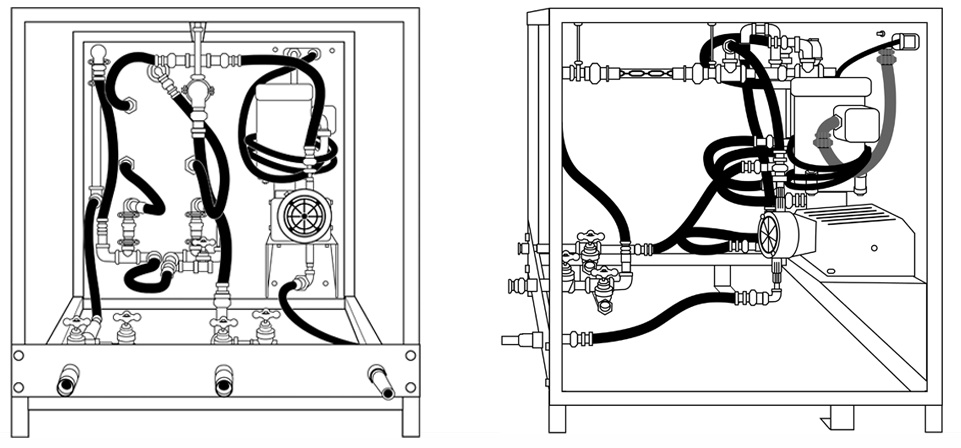

Gravity Belt Thickener is a 2.2 meter; skid mounted thickener.

The skid complete with; an automated flash blending polymer units, boost water pump, electronic controls, and a sludge discharge chute.

The GBT has a patented pressure plate installed at the end of the Gravity Zone to apply pressure to sludge at an adjustable rate.

The press will require a 480 three phase, 100 amp breaker power supply.

Water requirements for the press is fresh water at 50 gpm (35 gpm for spray bar) and 40+ psi.

Hoses for sludge feed are available upon request

Filter Press:

PF-1000 100 CF Duriron Filter Press:

Filter press Dewatering equipment is a 100 cf Duriron Plate and Frame press mounted on a 48 ft. tri-axle trailer. Unit has 92- 1200 mm plates and pumps for

medium pressure applications. The belt press is trailer is 48 ft. A conveyor is mounted under the unit for dewatered cake. The press will require a 480 three phase, 100 amp breaker power supply although continuous usage is about 80 amps each.

Water requirements for the press are:

Fresh water at 100 GPM and 45+ PSI.

Hoses for sludge feed are available upon request.

Ancillary Equipment

Polymer Blenders:

Polymer System Features

• Industrial Strength Stainless Steel Construction

• Designed For Easy Accessibility To All Working Components

• Single Stage Mixing

• Feed Rate Calibration

• Clear Visibility Mixing Chamber

• Water Flow Regulated Polymer Delivery

• Variable Feed Delivery Incremental Controller

• Low Point Drain Valves For Winterizing

• Sample Point For Jar Test Availability

Polymer System Benefits

• VFD For Faster Real-Time Adjustments

• Incremental Settings Allow For Minimum Polymer Waste Or Loss

• Long Term – Maintenance Free Operation

• Local Availability For Spare Parts (If Needed)

• Installation and Operation Is Very Simple

• Adaptable To Broad Spectrum Of Applications

• Low Cost For Operation Of Unit

• Long Term Reliability

• Very Fast Delivery

Pumps:

3” Progressive cavity, submersible pump

- 350gpm

- 480 volt, 3 phase with on/off switch

4” Centrifugal Self-Priming Trash Pump

- 350gpm

- 480 volt, 3 phase with VFD controls

6” Centrifugal Self-Priming Trash Pump

6” Centrifugal Self-Priming Trash Pump

- 350gpm

- 480 volt, 3 phase with VFD controls

4” Progressive Cavity, Rotary Lobe Pump

- 350gpm

- 480 volt, 3 phase with VFD controls

4” Grinder

480 volt, 3 phase with VFD Controls

15gpm Moyno Pump

- 120 volt, single phase with VFD controls

50gpm Moyno Pump

50gpm Moyno Pump

- 480 volt, 3 phase with VFD controls

Conveyors:

40’ Stacking Conveyor (36”)

- Maximum height, 15’

- 480 volt, 3 phase with on/off switch

40’ Stacking Conveyor (24”)

- Maximum height, 15’

- 480 volt, 3 phase with on/off switch